New Models For Sale in Owensville, MO

N/A N/A N/A N/A

Get in Touch

Info

Industry

N/A

Make

N/A

Model

N/A

Trim

N/A

Year

N/A

MSRP

N/A

Category

N/A

Subcategory

N/A

You May Also Like

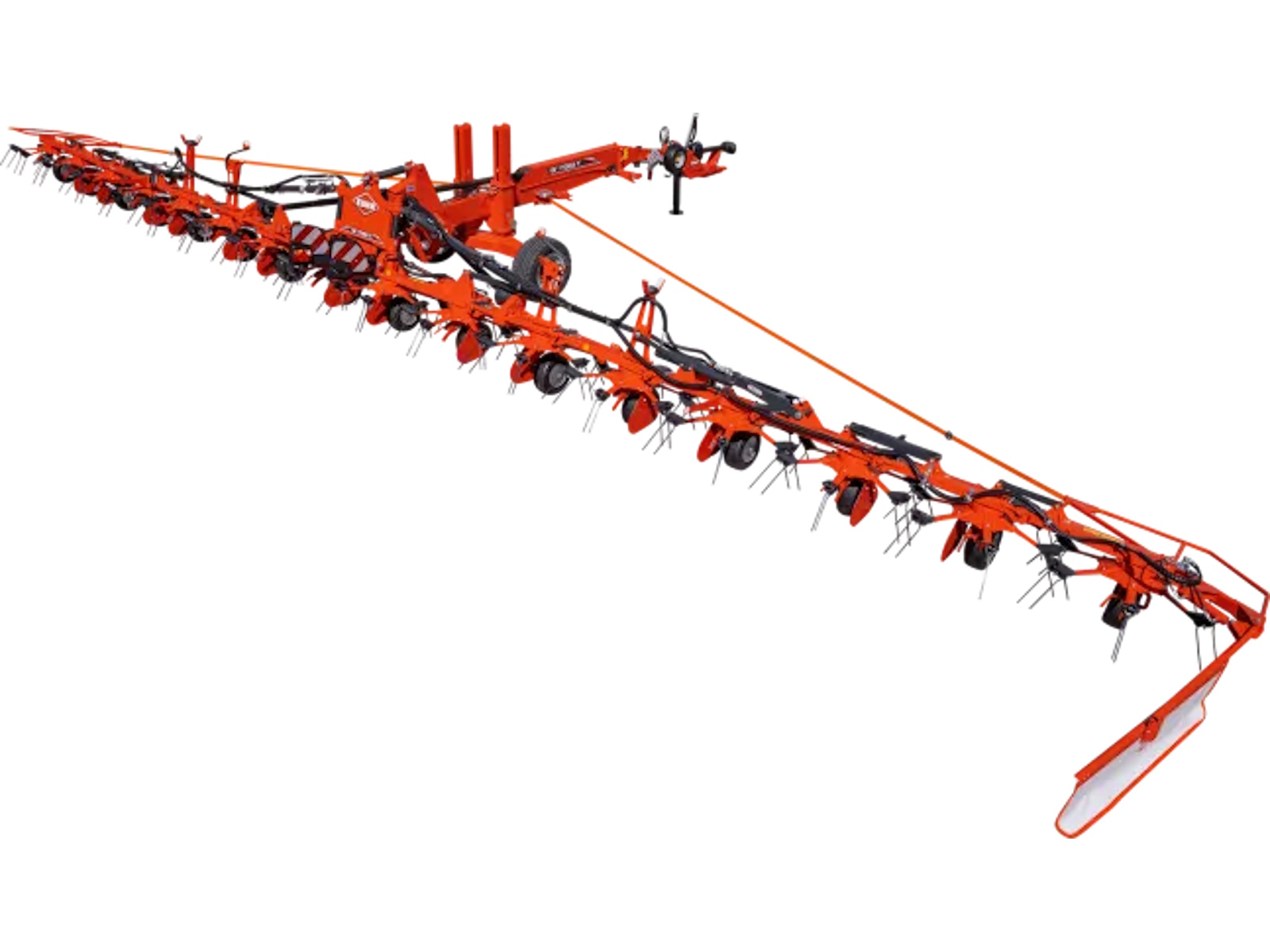

2025 Kuhn GF 10803 T

Get in Touch

Description

2025 Kuhn GF10803 T

Less Drying Time and Higher Outputs

Optimize your field efficiency with the GF 1003 T Series trailed rotary tedders, ranging in size from 25’7” to 56’5”. Both versatile and adaptable, these tedders are designed for producers and custom operators to harvest more crop in less time by easily transitioning from work to transport.

KUHN GF 1003 T Series trailed rotary tedders are ideal for both custom operators and hay producers. These machines provide exceptional tedding quality, resulting in a crop that is fully tedded over the entire width, and is efficiently and uniformly spread to maximize drying. Reduced drying times result in higher quality and nutritional value in hay and haylage.

The new OptiTedd rotors are the secret to rapid drying, excellent ground following and low incorporation of impurities in the crop, helping maintain maximum forage quality. These machines feature KUHN’s Headland Lift Control system, making them easy to lift and maneuver on headlands, while limiting the introduction of foreign materials like dust into the forage. Each of the rotor gearboxes are sealed, lubed-for-life and driven by KUHN’s patented DigiDrive® system, reducing maintenance. Despite the wide dimensions at work, these machines are incredibly compact in transport.

Fast and Uniform Crop Drying and Distribution

OptiTedd Rotors

OptiTedd rotors offer a steep angle of attack for complete crop inversion and fast, uniform drying. The improved rotor design increases robustness and ensures effective tedding in all conditions. Small-diameter rotors, available on GF 7903 T/8703 T/10803 T/17003 T models, feature a minimum distance to the center of gravity to reduce lift and horsepower requirements. Large-diameter rotors, featured on the GF 7803 T/7803 THA, excel at spreading long, dense crops.

High-Quality Tines

When it comes to tines that actually engage the crop, KUHN leaves nothing to chance: top-quality raw material has been wound into four coils with long tine fingers, giving you exceptional reliability. A defined attachment system to the arms results in an unmatched design life of at least 180,000 cycles. This provides several hundred hours of work before tine replacement is necessary. Asymmetrical tine finger length means both fingers engage the crop equally for a more consistent pickup. The tine guards prevent accumulation of debris around the coils.

Asymmetrical Tine Length

The asymmetrical tine length with longer outer fingers has several advantage to bring the machine’s tedding quality to perfection. This allows the outer finger to touch the crop earlier compared to symmetrical tines. It also ensures more complete tedding, along borders and between the rotors, where the tines overlap more in this sensitive area. Contacting the crop sooner means that the actual working width of each rotor is expanded and as a result, the entire machine working width is expanded.

ASYMMETRICAL TINE LENGTH PHOTO LEGEND:

A) Working Width of Rotor 1

B) Working Width of Rotor 2

C) Overlapping Area

D) Working Height

E) Sensitive Area

Quick Adjustment of Tine Angle

Whether in long or short, wet or dry crop, or different cutting heights, the pitch angle is adjusted without tools near the wheel supports. Always remember a steep pitch angle will decrease drying time and increase the nutritional value of the forage.

Headland Lift Control

Standard Headland Lift Control, on GF 1003 T Series tedders, makes the machine easy to lift and maneuver on headlands while limiting the introduction of foreign materials like dust into the forage. This is beneficial because the headlands do not need to be tedded twice.

Proven & Reliable Components

DigiDrive® Coupling System – A Legend in the Making

When a KUHN engineer came up with this drive coupling design, we knew that it would revolutionize the rotary tedder. This patented design made it possible to reliably drive a large number of rotors, yet fold them for unmatched transport ease, all with virtually no maintenance or repairs. Since the DigiDrive coupling’s inception, nearly 20 years have passed and more than 150,000 KUHN tedders are now being used across the world to ted hay with the ultimate reliability.

The DigiDrive contains case-hardened forged steel fingers for improved wear resistance. Synchronization of rotational movement is outstanding both in work and in transport where the components are folded to nearly 180° to reduce the machine’s space requirement. The DigiDrive is a highly reliable system requiring very little maintenance – no daily greasing necessary!

Rotor Housings – Made to Last

With rotors driven by DigiDrive couplings and lubed-for-life rotor housings, the greasing points are limited to a relatively few pivot points allowing you to spend more time in the field and less time greasing.

They are supported by large diameter, double-row angular ball bearings.

The thoroughly sealed rotor housing prevents lubricant leaks or introduction contaminants.

The robust mounting of housings to the edge of the rectangular frame maximizes strength and durability.

Stress-Reducing Straps

The 17003 T tedders utilize straps to reduce stress on the main frame and rotor structures. This allows fastening to the rotor ends, keeping the two sections stable while reducing oscillation. The straps also double as safety guards, replacing the metal guards. When folding for transport, the two straps automatically wind up like a seat belt.

Excellent Ground Adaptation and Transportability

Border Tedding Along Field Edges

For clean, careful tedding next to fences or neighboring fields, GF 1003 T Series tedders are equipped with a border control system. On slopes, the border setting is particularly beneficial for controlling the direction of crop spread and obtaining an optimal spread pattern.

An optional hydraulically controlled curtain deflector limits the discharge on the right side to prevent spreading outside of the field.

Innovative Ground Following

The GF 13003 T and 17003 T come standard with GSC (Ground Save Control) system which allows the rotor gear to train to swing independently of the carrying frame.

These machines have excellent ground following with their small rotors that are under 5’ in diameter, which allows for uniform tedding across the whole field. There is individual articulation between each rotor and equal spacing between the rotors and tires for better ground following.

Intelligent Folding Design Folding System for Narrow Transport

Unfolding or folding operations are quick and easy using the in-cab control box on select models. Time lost when changing fields is reduced to a minimum so you can focus on achieving maximum daily output.

The folding system allows the transport wheels to lower and combine with the rotors tilting forward. While in transport position, height is reduced, load distribution on the tractors is optimal and road transport at high speeds is ideal. The incredibly narrow transport width and the wide transport undercarriage combine for easy maneuverability and stable road transport.

Crop Deflectors

Operating in short, sticky crops or long, late season crops can be a challenge when the crop wraps in the wheel column, resulting in frustrating downtime spent clearing the mess. These tedders are fitted with crop deflectors as standard.

Info

Industry

Agriculture

Make

Kuhn

Model

GF 10803 T

Trim

Base

Year

2025

MSRP

N/A

Category

Tillage

Subcategory

Tedder

Specs

Length

Transport: 14'9''

Width

Working: 35'5" | Overall: 36'9" | Transport: 9'10''

RPM

PTO Speed: 540 rpm

Power/Horsepower

55 hp

Height

Transport: 10'10'

Weight

4,175 lbs

Tires

Central Rotor: 18 x 8.50-8 | Outside Rotor: 16 x 6.50-8 | Transport: 26 x 12.00 - 12

You May Also Like

N/A N/A N/A N/A

Get in Touch

Info

Industry

N/A

Make

N/A

Model

N/A

Trim

N/A

Year

N/A

MSRP

N/A

Category

N/A

Subcategory

N/A